Hurry, before it’s gone!.

WINTER DEALSPromo Code:

KINWA2025Hurry, before it’s gone!.

WINTER DEALSPromo Code:

KINWA2025Thursday, 29 January 26

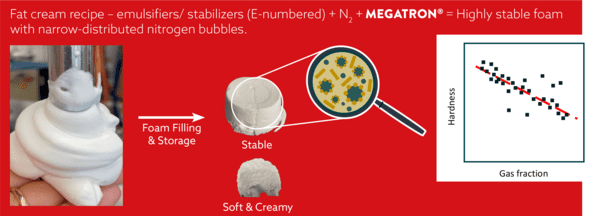

To achieve a stable foam for topping without the use of emulsifiers or stabilizers.

The incorporation and stabilization of air and other gases in food foams can be facilitated with a fat crystal network. When protein is also present, interaction between this components produce a stable foam with bulk characteristics1. In this case, the stabilization of N2 is given by the adsorption of protein at the interphase and the fat crystals stabilizing the bulk. Temperature is crucial in this process. Ask for the continuous scraped heater exchanger SWT20RH to avoid butter fat formation and facilitate foaming.

Softer and creamier texture could be achieved using the membrane technology for the formation of foamy toppings.

Do you want to have more information? Please contact us here or send us an email to science@kinematica.ch.