Hurry, before it’s gone!.

WINTER DEALSPromo Code:

KINWA2025Hurry, before it’s gone!.

WINTER DEALSPromo Code:

KINWA2025Monday, 08 Dezember 25

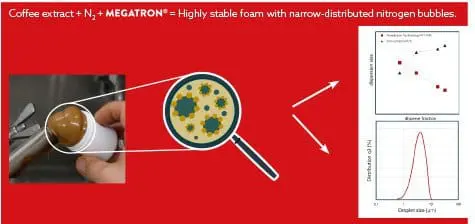

To achieve a monomodal and stable foam under gentle conditions to avoid flavor loss.

In several food products gas bubbles are incorporated to improve texture and/or its appearance. At the same time, there is an increased interest in foamed structures in food products since it helps to reduce the energy density while delivering to the consumer different and better experiences such aroma release or visual enhancing1.

Monodispersed and small bubbles lead to a more stable foam even at high gas fractions2,3.

In the case of the conventional rotor-stator foaming units, high gas fractions result in larger bubble sizes decreasing the stability over time of the resulting foam.

On the contrary, the gentle breakup method of the bubble in the membrane technology of Kinematica allows the increase of the gas fraction with simultaneous decrease of the bubble size.

This difference on the detachment method from the surface on both technologies also explains the reduced energy consumption. This reduces the temperature increase and therefore the flavor loss during processing.

The membrane technology has a promising future in different industries to generate monodispersed foams4.

Do you want to have more information? Please contact us here or send us an email to science@kinematica.ch.